Clone of Clone of Kraftstoff- und Bremsleitungen

Cooper Standard bietet Produkte für den traditionellen Kraftstoff- und Bremsenmarkt sowie für verschiedene Arten von Freizeit-, Spezial- und Industriefahrzeugen an. Gleichzeitig treiben wir neue Innovationen voran, um neue Bedürfnisse und Anforderungen an die Technologien zu erfüllen.

- Rohrbiegen

- Verkupfern

- Hartlöten von doppelwandigen und Schweißen von einwandigen Rohren

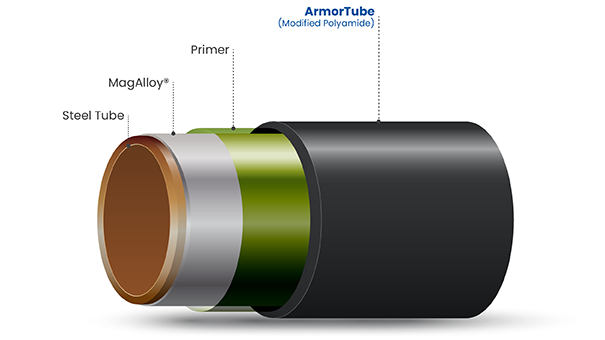

- Galfan®-Legierung oder MagAlloyTM (Beschichtungsverfahren Schmelztauchen)

- Galvanisches Verfahren mit E-Zinc

- Farbbeschichtung

- Extrusionsverfahren für Nylon (PA12, PA 612 sowohl leitfähig als auch nicht leitfähig)

- PP-Extrusionsverfahren über Metallrohre

- Nylon-Abisolierung

- PP-Schälen

- Schneiden

- Endformung

- Crimpen

- Entgraten

- Lecktest

- Herstellung von Kunststoffrohren

Kraftstoffverteilerleitungen

- Hartlöten

- Biegen

- Montage

- Leckprüfung

Spritzgießen

- Schnellverbinder