Agricultural & Turf Equipment Sealing and Fluid Handling Solutions

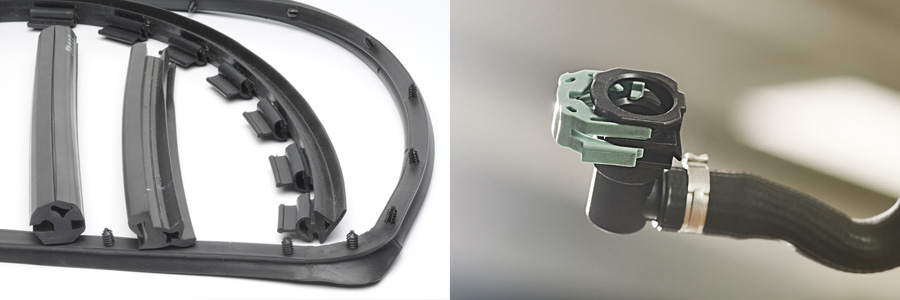

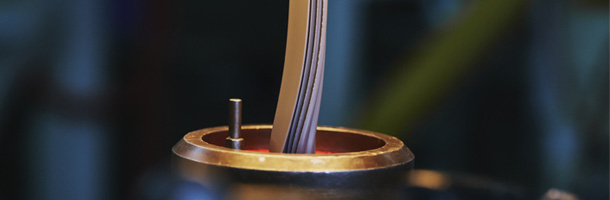

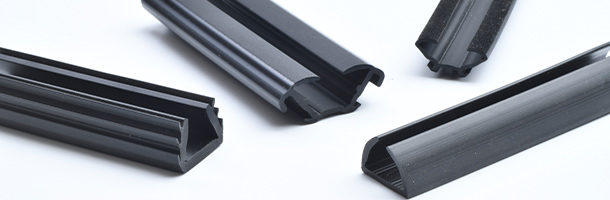

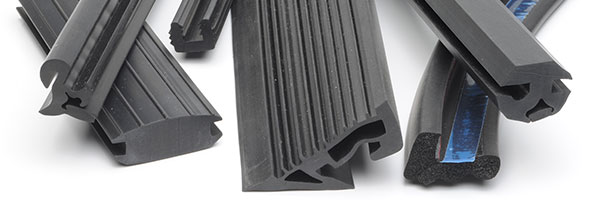

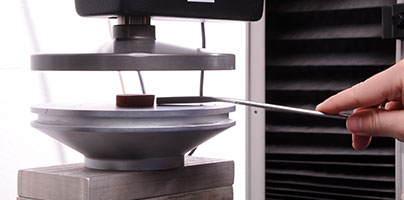

Cooper Standard Industrial & Specialty Group (ISG) offers a unique combination of expertise, including engineering, materials, prototype/testing/validation and production, to help our agricultural equipment manufacturer partners design, develop and optimize any new or existing seal or gasket component for optimum performance in their machinery. We can help design and develop cab seals that work to keep good air in, and agricultural chemicals, rain, mud and humidity out. We can also develop fluid and air handling systems to support the equipment's performance and the user's comfort. Both of these systems are designed and built to support long-term performance.

Cooper Standard ISG seals robustly and reliably stand up to the wear and tear of long hours of operation in the harshest conditions, as well as the toughest operator handling so that farmers can work comfortably and safely with maximum productivity.

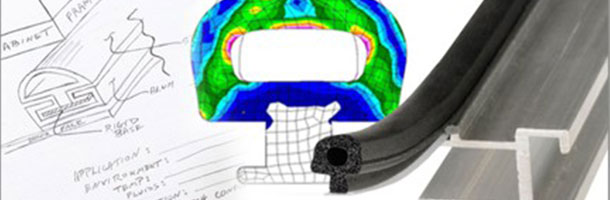

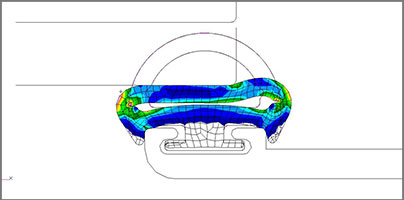

Cooper Standard ISG also utilizes Finite Element Analysis Technology (FEA) and Computational Fluid Dynamics (CFD), powerful software tools applied to design and development of our sealing and fluid handling systems for superior product performance.

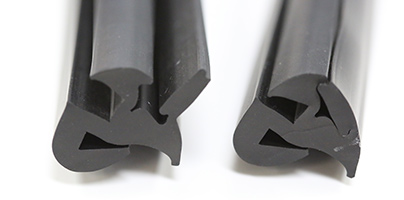

Further, Cooper Standard ISG’s Crimp on Flange (COF) technology effectively doubles the pull-off force of glass cab door seals, keeping them secure through thousands of cycles as well as the rough handling of the operator.