State of the Art Coatings for Superior Industrial Seals

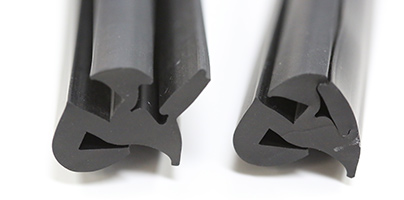

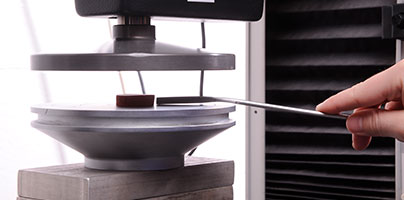

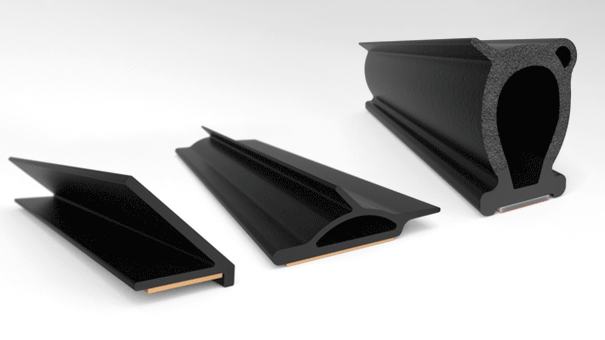

Cooper Standard ISG delivers world-class coatings expertise to our partners, with in-house competencies in both chemical and mechanical engineering. Coating a seal for your application not only ensures a longer service life, but it also takes your product to the next level by enhancing properties such as abrasion resistance, weatherability, and more. Our coatings are made of high-performance, elastomeric material that are cured right onto the sealing material in the extrusion process, giving you confidence that it won't fail in your application.

Cooper Standard ISG delivers world-class coatings expertise to our partners, with in-house competencies in both chemical and mechanical engineering. Coating a seal for your application not only ensures a longer service life, but it also takes your product to the next level by enhancing properties such as abrasion resistance, weatherability, and more. Our coatings are made of high-performance, elastomeric material that are cured right onto the sealing material in the extrusion process, giving you confidence that it won't fail in your application.

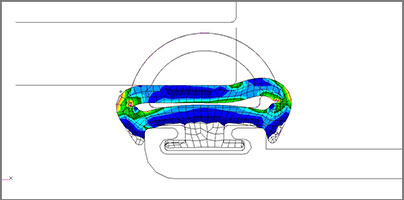

At Cooper Standard, we work with you as an extension of your team to help you design and develop the most effective sealing solutions from scratch, while also solving opportunities and challenges for whatever your application demands.