Lighting Fixture Sealing Solutions

Lighting fixtures for indoor and outdoor commercial, industrial and institutional grade applications, such as schools, hospitals, tunnels, and stadiums, demand robust construction to help guard against environmental challenges like heat, water, dust, and more.

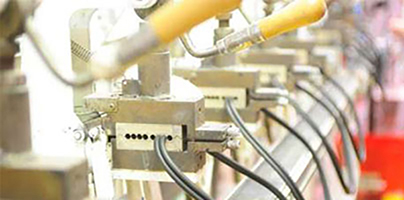

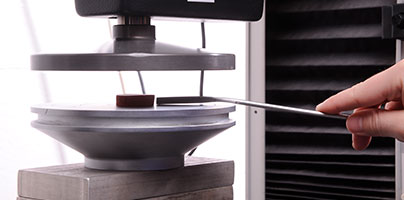

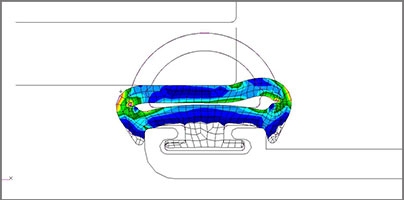

Cooper Standard Industrial & Specialty Group (ISG) delivers specialized knowledge in a wide variety of materials for your lighting needs, including sulfur-free, non-fogging silicones. We also provide expertise in engineering capabilities, including computerized finite element analysis designed to help create the optimum sealing solution to help meet the demands of any lighting application.

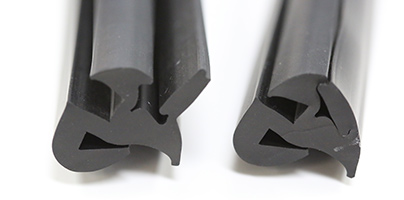

Our extruded and molded seals are designed to keep water, dirt and fog out, all while building long-term durability and ensuring that UL, NEMA, IEC and other regulatory demands are met.

Cooper Standard ISG can design or re-design seals for various light fixtures, such as LED, fluorescent, compact fluorescent, mercury vapor, and high-pressure sodium, to help lower overall cost and create optimum lamp protection, performance and operation.