Powersports Sealing and Fluid-Handling Solutions

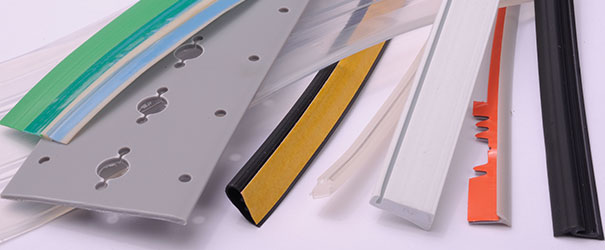

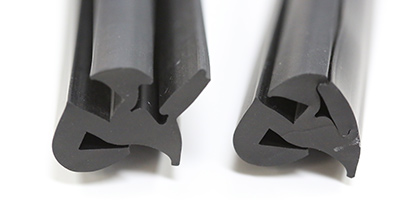

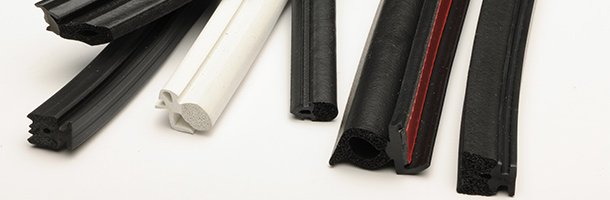

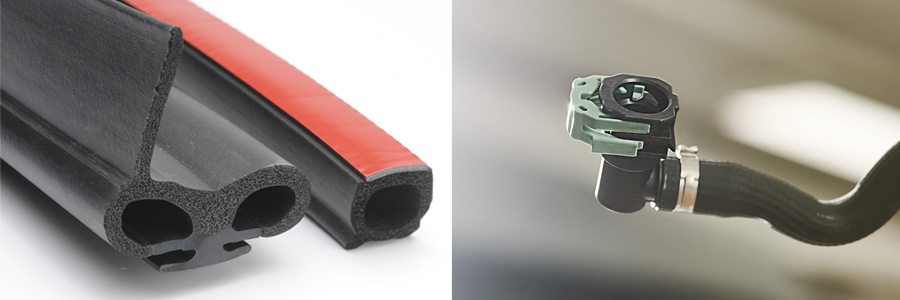

Cooper Standard Industrial & Specialty Group (ISG) designs and manufactures custom or catalog seals and fluid-handling solutions for powersports vehicles of all kinds, including ATVs, off-road, snowmobiles, motorcycles, personal watercraft, pontoons, jet skis and more. Whether our customers are in need of underhood, compartment or cab seals, or hoses, tubes and other fluid handling components, we will ensure that our solutions perform and stand up to the challenging demands of vehicle applications.

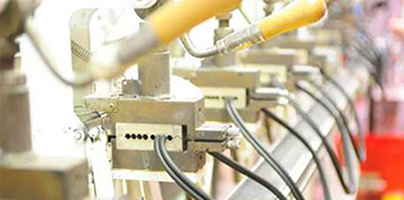

Our wide-variety of expertise ranges from materials science, engineering, value-added capabilities, as well as other performance tools, such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). FEA and CFD technologies are designed to precisely fine-tune product design before production, significantly reducing the sample development process and providing trusted products to ensure powersport machines run at peak performance.

Our engineers help develop seals and fluid handling components from the ground up or research ways to optimize your current components for improvements. We have developed customer-focused technologies to ensure the best fit, assembly ease, and solid, stay-in-place stability that performs for the long term no matter what the terrain—or your customers—can dish out.