Innovative Sealing Solutions for Enclosures Applications

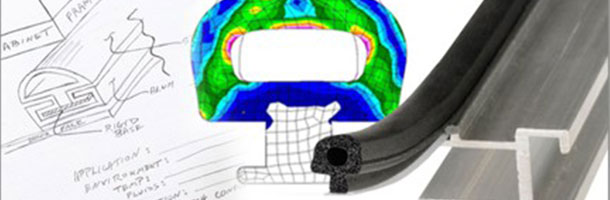

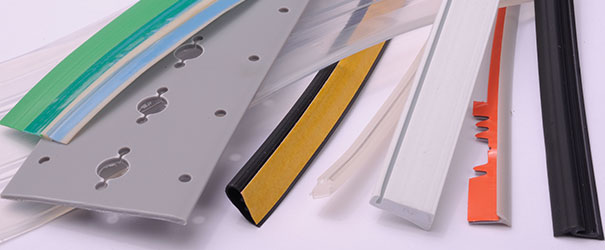

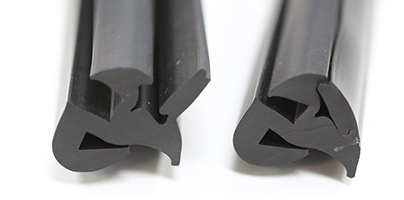

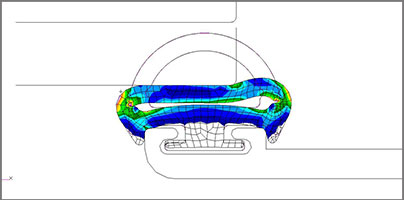

Cooper Standard Industrial & Specialty Group (ISG) designs and optimizes highly effective seals and gaskets for portable and stationary enclosures such as boxes, cases, pails, drums, cabinets and containers. ISG materials and engineering expertise create customized sealing solutions that ensure sensitive electronic or medical equipment stays isolated from ambient conditions, while hazardous chemicals remain safely and securely within their protective vessels. We provide expertise in computerized finite element analysis designed to help create sealing solutions to help meet the demands of any enclosure application.

Cooper Standard Industrial & Specialty Group (ISG) designs and optimizes highly effective seals and gaskets for portable and stationary enclosures such as boxes, cases, pails, drums, cabinets and containers. ISG materials and engineering expertise create customized sealing solutions that ensure sensitive electronic or medical equipment stays isolated from ambient conditions, while hazardous chemicals remain safely and securely within their protective vessels. We provide expertise in computerized finite element analysis designed to help create sealing solutions to help meet the demands of any enclosure application.

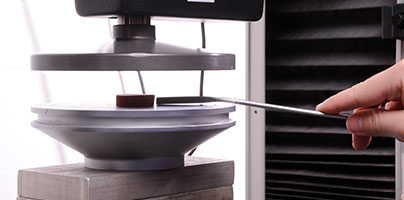

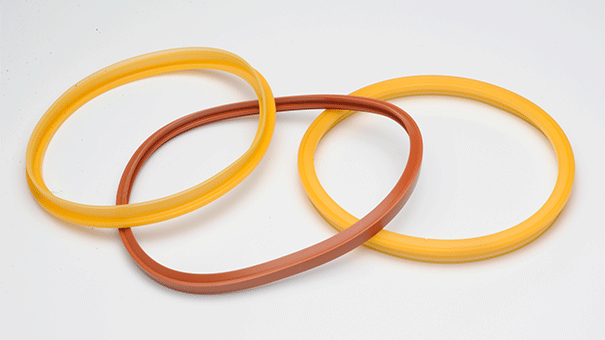

Cooper Standard ISG works to identify the optimum balance of properties such as compression set, water tightness, chemical resistance, low-temperature resistance, fire and heat resistance, dirt and dust protection, and more at a competitive price point.