Innovative Sealing Solutions for Boats, Motors and other Marine Applications

Cooper Standard Industrial and Specialty Group (ISG) offers a wide variety of expertise, including engineering, materials and other value-added solutions to help protect marine boating equipment from relentless weather conditions and vibration. Whether it's ski boats, pontoons, yachts, or large cruisers, we help protect watercraft applications from corrosive marine environments, helping ensure performance, longevity and brand loyalty for years to come.

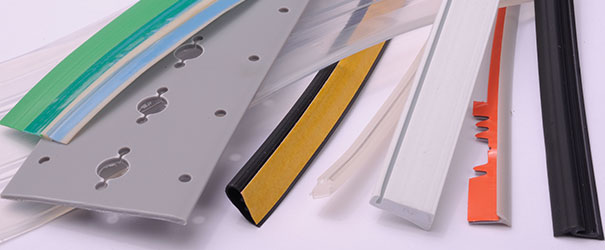

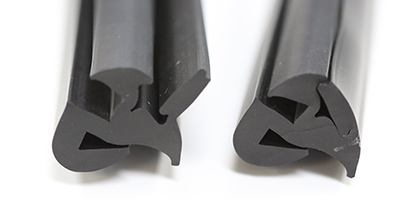

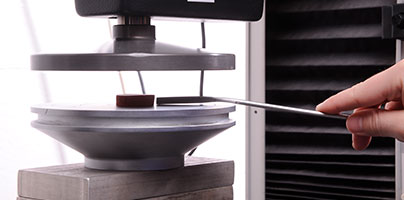

Our wear and abrasion-resistant sealing solutions have been used in applications for nearly 50 years. Window seals are a particular specialty, and we help protect large, complex, and intricate windshields with seals that resist fading and deterioration and keep glass tightly engaged and free from rattling or breakage. Additionally, we help increase service life and operating performance in high horsepower motors, with highly effective cowling seals designed to keep components safe from water, oil and other threats.

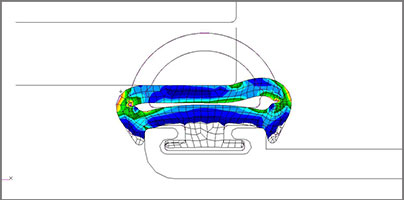

Cooper Standard also utilizes Finite Element Analysis (FEA) and Computation Fluid Dynamics (CFD), powerful software tools used to optimize seal designs and development for superior product performance.