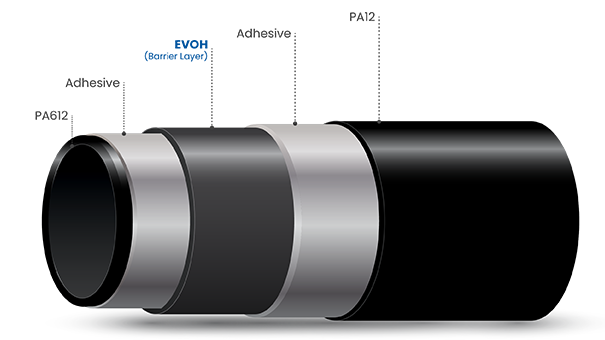

LoPerm 4000E Multilayer Tubing

Cooper Standard’s LoPerm 4000E is a multi-layer, low permeation and low oligomer washout thermoplastic tubing construction. This innovative tubing solution is specifically designed to meet the increasingly stringent fuel standards of today. By using LoPerm 4000E, customers can experience a reduction of at least 80% in oligomers and washout buildups compared to traditional tubing options. This advancement contributes to an extended vapor system life expectancy, helps prevent unexpected damage to vehicles and ultimately helps reduce potential warranty claims.

As industry leaders known for providing best-in-class tubing solutions, the addition of LoPerm 4000E to Cooper Standard’s portfolio is another example of our ongoing commitment in manufacturing and engineering to develop innovative solutions that address more stringent government requirements and adapt to global industry needs.